Automated Voice Coil Assembly for Audio Devices

At a glance

Customer

An undisclosed leading audio device manufacturer.

Problem

The complex, time-consuming, and manual process of voice coil assembly in audio devices.

Solution

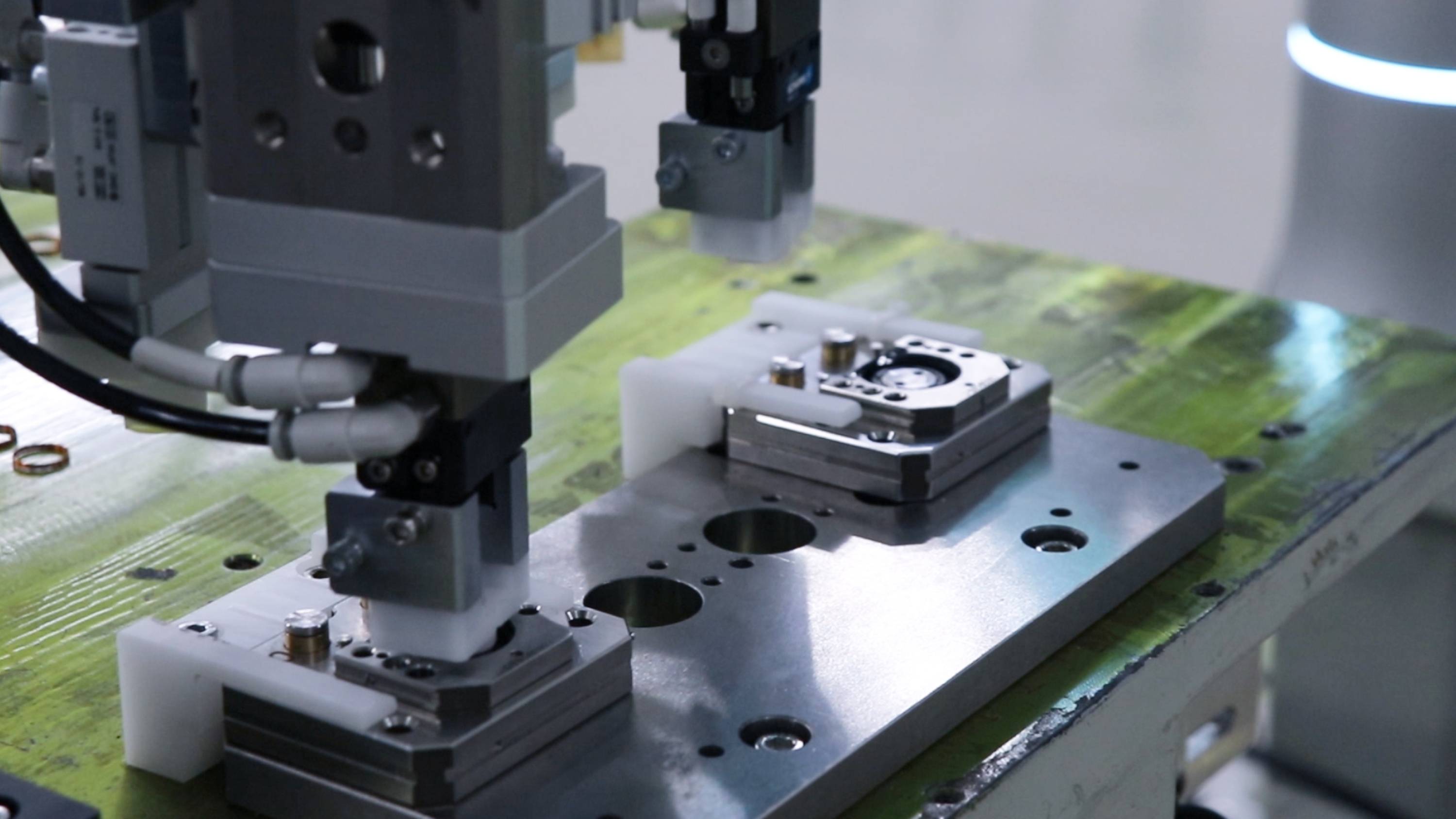

Flexiv provided a unique interference-fit assembly solution leveraging advanced computer vision and industry-leading force control technology.

Key Features

Adaptive grasping, force-controlled searching, and component insertion.

Advantages

Enhanced assembly quality, improved operational efficiency, flexibility, and the universality of the assembly process.

Overview

With the ever-increasing demand for smartphones, tablets, and wireless earphones, the audio device industry has, in turn, seen increased demand. As the audio devices become smaller and more complex, the audio component assembly process becomes more challenging to automate. This, in turn, leads to lower automation rates and higher production costs. To combat this, Flexiv created a solution to automate the installation of the minute and delicate components that form the 'voice coil', a core element found in all speakers, earphones, and other audio-based devices.

Case Study Customer

(Subject to an NDA)

Voice coil assembly is a difficult and time-consuming process that the customer sought to automate. A challenging task due to the irregular shape and deformable nature of the wires that form the coils, the client clarified that they wished for a coil assembly yield of over 99% and a reduction in installation angle deviations by at least 25% compared to manual processing.

Flexiv's Solution

Flexiv provided a unique solution for the interference-fit assembly of voice coils, which leveraged advanced computer vision and Flexiv's industry-leading force control technology.

Our solution achieved pinpoint accuracy in coil positioning and rotation using standardized components and AI-powered vision.

With force-controlled handling eliminating coil deformation during manipulation and assembly phases, workpiece damage was negligible. This damage reduction was also empowered via the implementation of the vision-guided insertion, which ensured accurate coil insertion.

Technical Features

Adaptive Grasping

Flexiv's proprietary force-control technology adapts to positional errors, ensuring accurate and non-deformable grasping.

Force-Controlled Searching

Precise placement into installation grooves is enabled using a fine force-controlled -searching algorithm.

Force-Controlled Insertion

Specific pressure is applied by the robot in conjunction with a slight oscillation until a designated force value is reached and the force-controlled insertion process is complete.

Solution Advantages

Enhanced Quality

Flexiv's voice coil assembly process has a yield rate greater than 99% and an angle deviation rate below 25%.

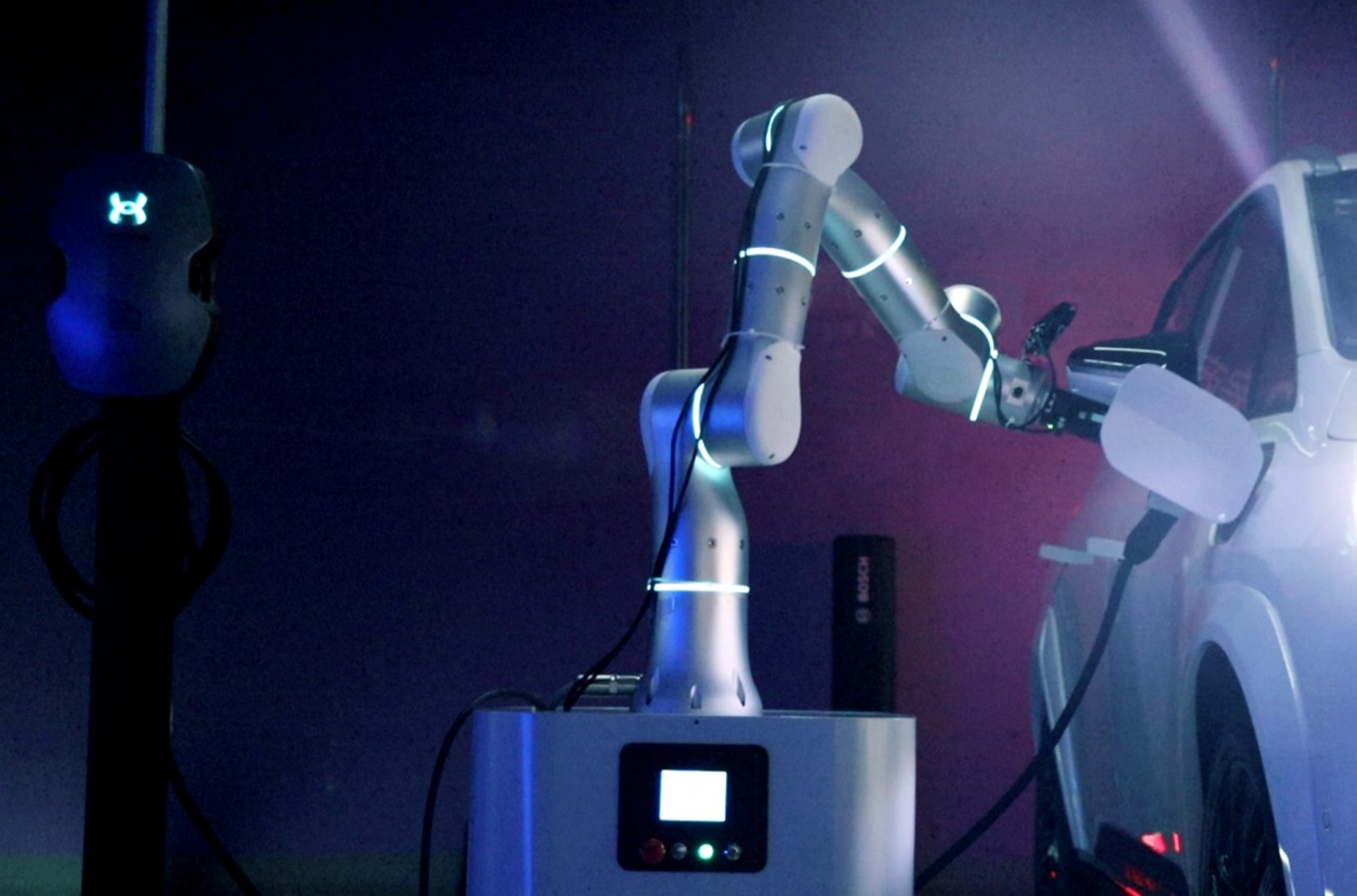

Automated Efficiency

Able to fully replace the manual processing of voice coils, Flexiv's solution provides an improved throughput rate and the ability to operate in a 'lights out' manufacturing environment.

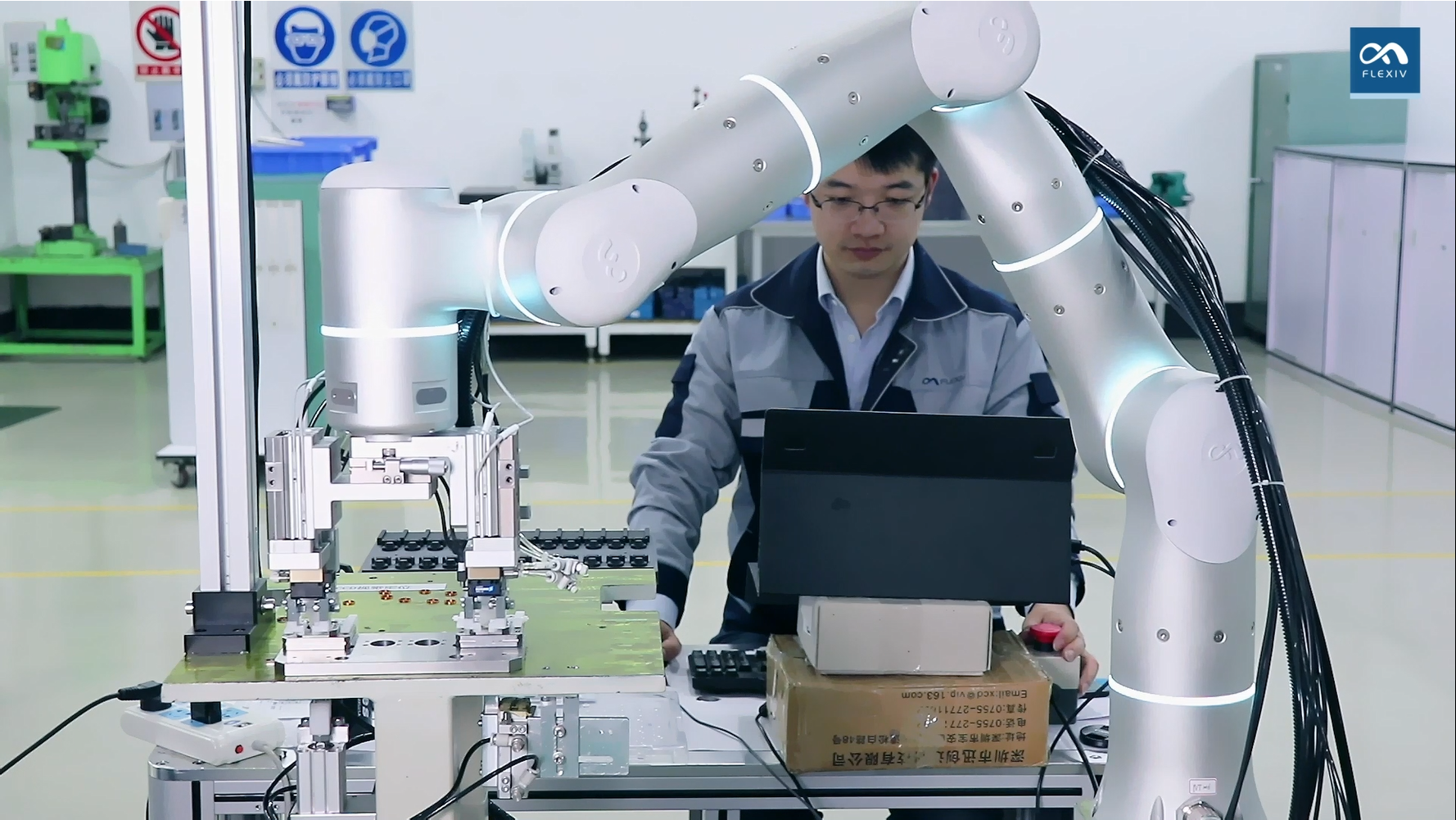

Flexibility and Universality

Leveraging the robot's inherent force control capabilities and ease of programming, a user can re-task the robot quickly and efficiently with minimal downtime.