Assembly Automation

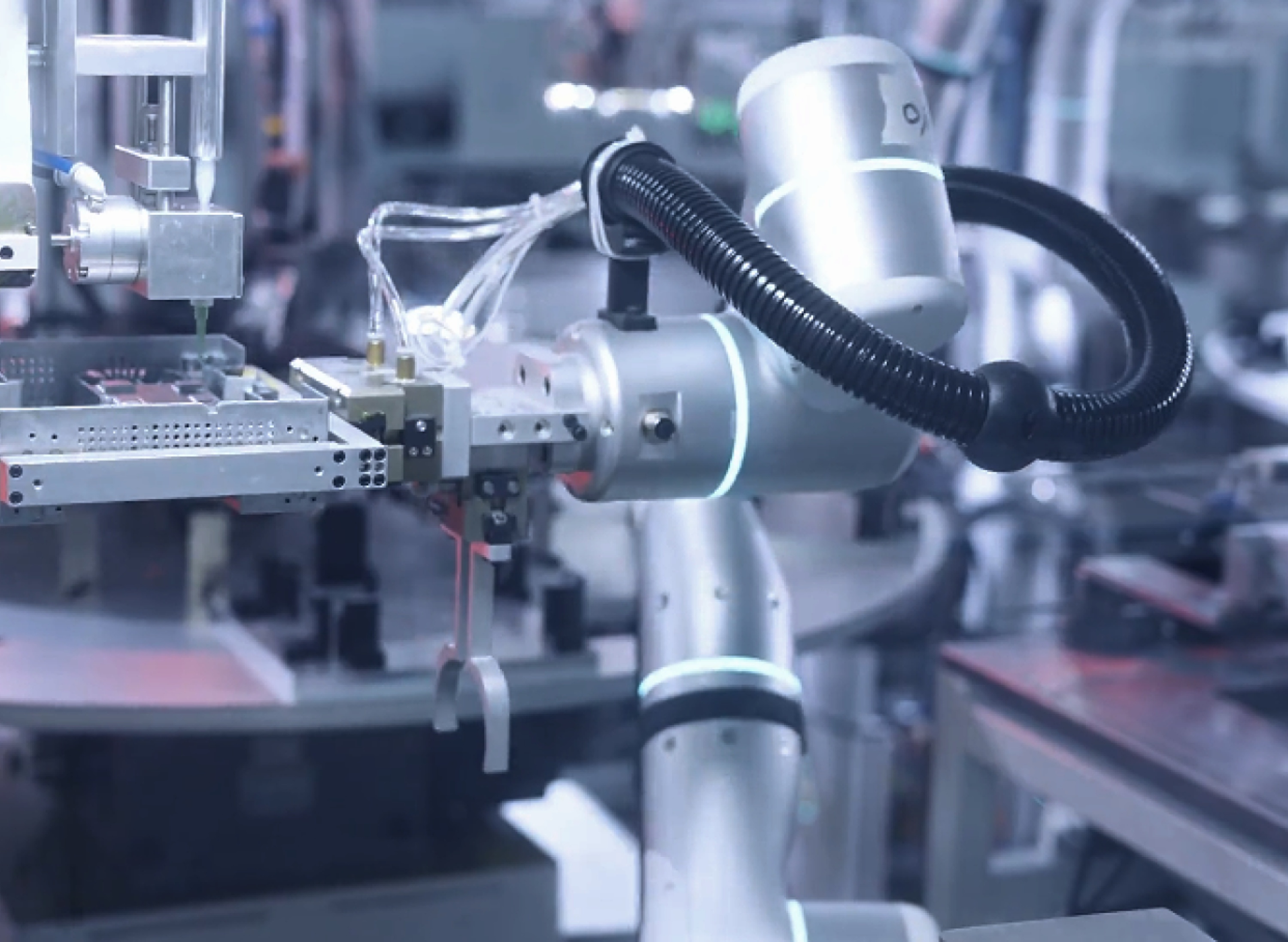

Empowered by integrated force/torque sensors, Flexiv adaptive robots are designed to be versatile and effective in assembly tasks that range from material loading and screw fastening, to the precise component alignment and installation of connectors. Utilizing an intuitive programming interface, users can effortlessly automate complex tasks using the robots, ensuring smooth integration into existing processes.

Contact Us

Full automation

Machinery cutback

Supporting machine was reduced by 56%, simplifying the production process

24/7

Run continuously without downtime

Incredible precision

+/- 0.05 mm repeatability +/- 0.01 mm assembly accuracy

Flexiv Rizon robot arms are the perfect solution for businesses that want to automate even the most challenging tasks. With a repeatability of +/- 0.05 mm and an assembly accuracy of +/- 0.01 mm, the Rizon adaptive robots are capable of handling even the most delicate components with precision. The 7-DoF articulation of the Rizon arms makes them ideal for electronic component assembly, where precise movements and delicate part handling are essential. And thanks to Flexiv Elements, the drag-and-drop programming interface, these robots can be easily configured and operated, saving you time and money, as well as eliminating additional expenses associated with robot programming and setup.

Precise force control

0.03N

Force sensing accuracy

Adaptive

Easily adjust to accomodate position errors with precise force control

Assembling FFC and FPC can be tricky. Too much force can damage the connectors. Flexiv's robot arms use vision and force guidance to assemble FFC and FPC connectors with precision. Various connectors can be identified, localized, and tracked using Flexiv's 3D vision system. Upon grasping the connector, Flexiv’s proprietary force-guided insertion can be used to ensure safe and secure assembly of the header. With a force-sensing resolution as low as 0.03N, Flexiv’s robot can adapt to even the most subtle changes, ensuring that cables are assembled consistently within the required cycle times.

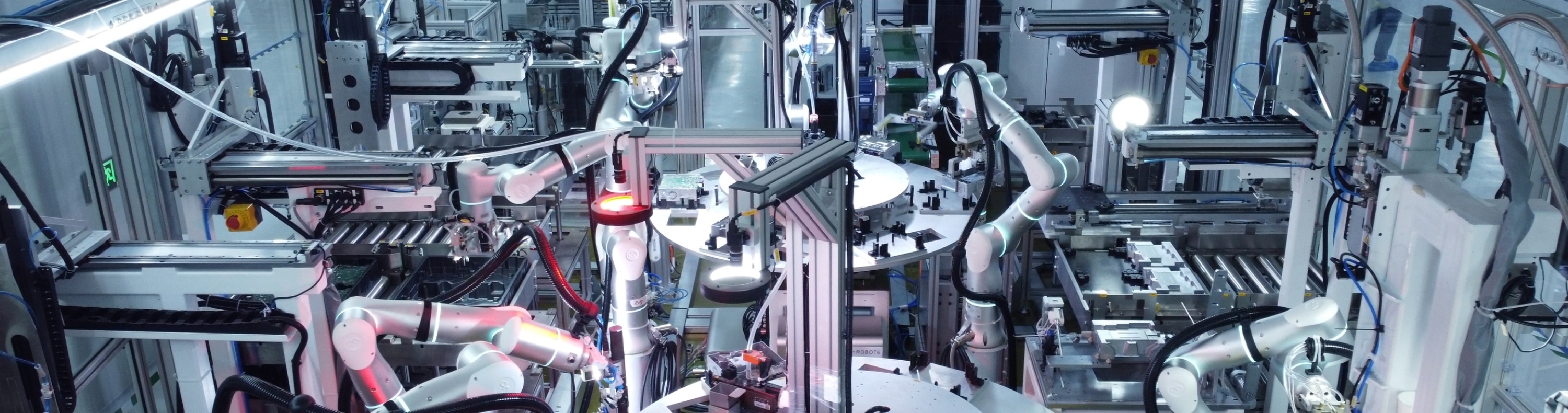

Dexterous and intelligent

Shared intelligence

Flexiv’s robots can coordinate with each other during operatiion

Robust operation

Adapt to variations in geometrical tolerances

Incredible precision

+/- 0.05 mm repeatability +/- 0.01 mm assembly accuracy

Flexiv's adaptive robots use force-controlled arms to achieve human-like insertion motion, which provides compliance and stiffness in different directions. Using these capabilities. Flexiv's robot is actively working with Tier 1 automotive suppliers to automate dashboard assembly processes. Working in harmony within the assembly station, multiple robot arms seamlessly locate, pick up, and collaboratively assemble various injection-molded components, pick them up, and collaboratively assemble them. Flexiv's 3D vision system locates parts with pinpoint accuracy, enabling robots to pick parts up preciously and accurately from a bin, conveyor, or moving AMR. Executing a force-guided insertion during assembly, Flexiv's adaptive robots achieve assembly accuracy of +/- 0.01 mm with force sensing seamlessly integrated into the control architecture. When assembling large parts prone to deflection, multiple robots can collaboratively work together using force control to effectively compensate for any deflection.

Reliable and robust

AMR-friendly integration

Design with multiple industrial communication protocols to work seamlessly with any AMR

Adapt to position errors

Overcome inherent limited position accuracy from AMR

Machine tending is one of the most popular applications for robots. Frequently, the need arises to tend to multiple machines simultaneously. However, due to machines not operating in sync, robots are often installed on autonomous mobile robots (AMR), allowing them to navigate and tend to machines once their tasks are finished. Successful loading and unloading rely heavily on accurate docking in AMRs. However, achieving high precision can be challenging in practice due to positioning errors from both the AMR and the machine itself. To solve this challenge for a PCB manufacturer, Flexiv integrated its robot arm onto an AMR and employed real-time force guidance to adapt to errors. This innovation empowered the robot fleet to achieve dependable and secure loading and unloading operations.

Request a free expert consultation

Ready change the way you automate or looking for a particular adaptive robot application? Complete the form on the right and we will get in touch with you.