Automated Welding Debris Removal in Automobile Manufacturing

At a glance

Customer

A leading automobile manufacturer (Subject to an NDA).

Problem

High costs, human error, and inconsistencies associated with manually removing welding debris.

Solution

Flexiv introduced an automated grinding solution using the Rizon 10 robot with off-the-shelf electric grinding tools.

Key Features

Simplified operations, human-inspired adaptability, safe and efficient human-robot interaction.

Advantages

Consistent, high-quality results, cost-effectiveness, and ease of deployment.

Overview

Welding is a vital element of the automobile manufacturing process. However, it frequently leaves various surface defects, such as welding spatter, slag, and uneven surfaces. These defects can significantly impact the later stages of assembly, especially if the affected surface is to be mated to another or if it is going to be painted.

Complex shapes, large sizes, tolerance variations, and throughput demands of the workpieces make automated grinding and polishing a significant challenge.

Most automobile manufacturers rely on manual labor to perform body surface grinding and polishing tasks. However, this approach dramatically increases the production cost while inserting the possibility of human error.

Case Study Customer

(Subject to an NDA)

The customer's previous strategy for welding spatter involved applying an anti-spatter compound to the surrounding surfaces before welding. Given the limited effectiveness of the anti-spatter compound, manual labor was used to remove the compound and the spatter. This resulted in a laborious and expensive process, which made it difficult to maintain a consistent level of quality.

Flexiv's Solution

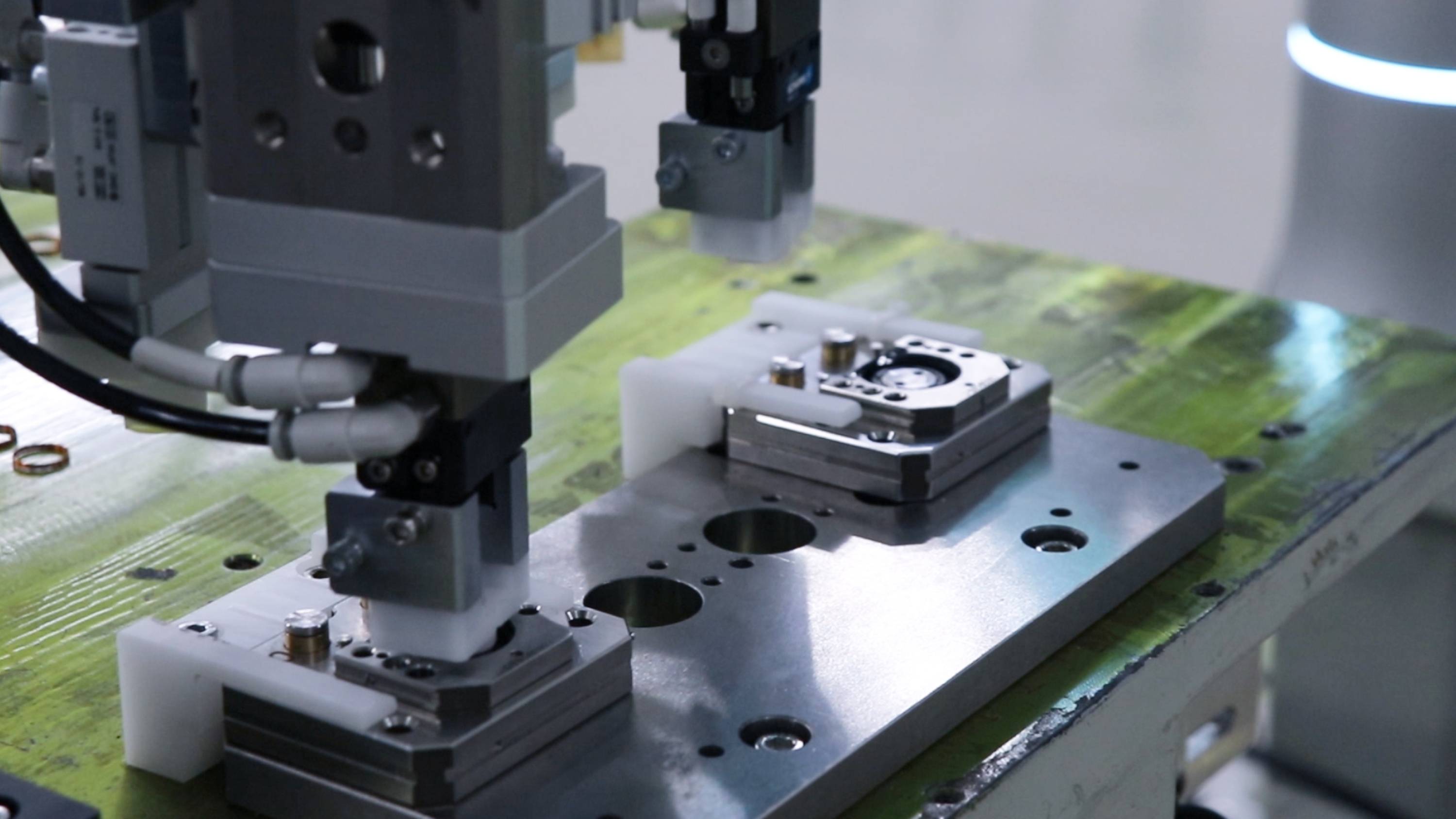

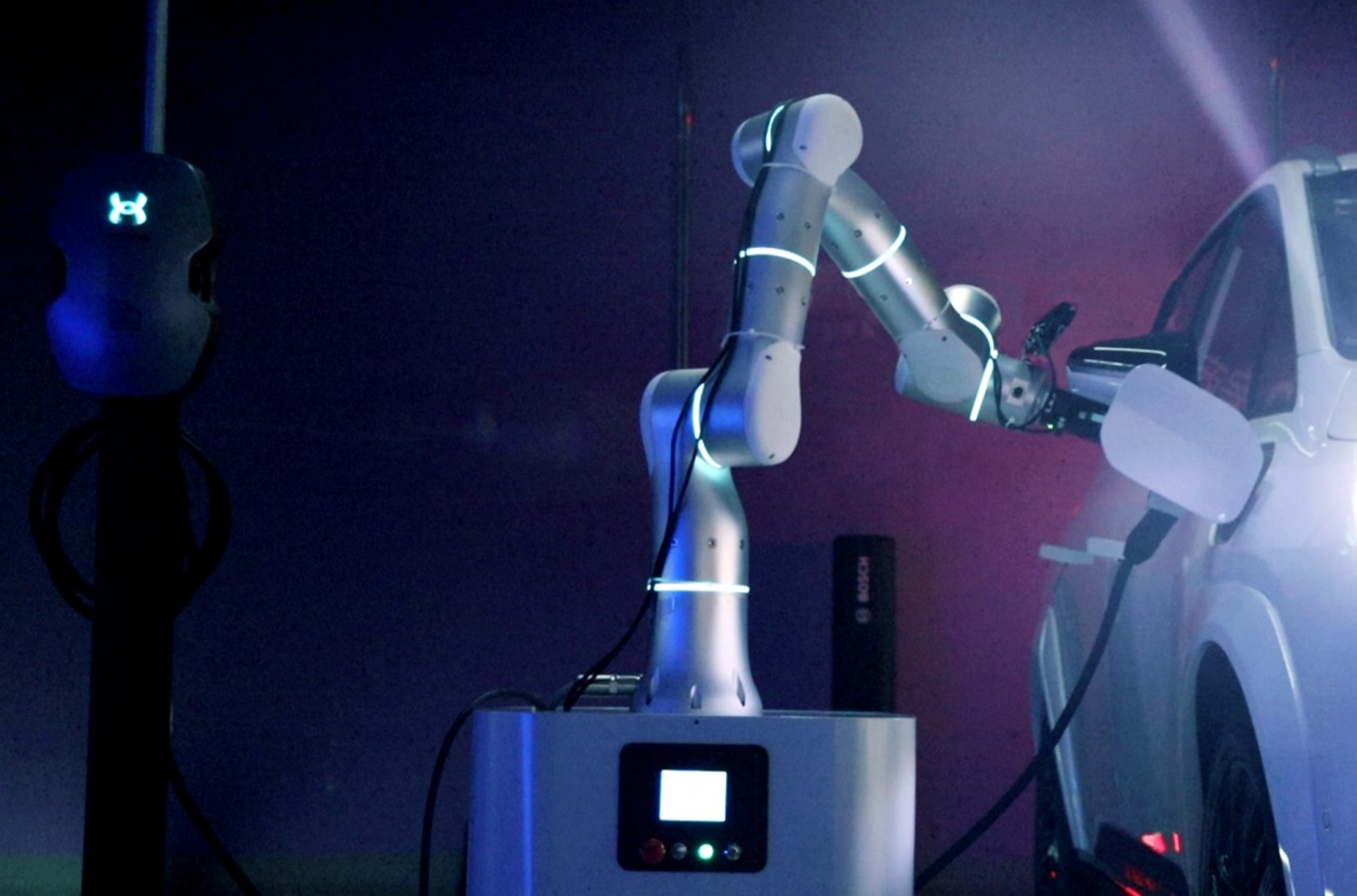

Leveraging its full-body force control capability, Flexiv's Rizon 10, equipped with standard off-the-shelf electric grinding tools, provided the customer with a fully automated grinding solution.

Thanks to its state-of-the-art hybrid motion and force control technology, the Rizon 10 can adapt to complex curved surfaces to deliver superior polishing results without requiring additional force control tools or specialized grinding equipment.

By packaging the polishing process into meta-operation primitives, and using straightforward trajectory dragging/teaching, in combination with a graphical programming interface, the skill-based barrier to entry is removed, and the deployment time is massively decreased.

Technical Features

1. Flexiv simplifies the programming of the material removal process by including multiple user-friendly meta-operations into the Flexiv Elements system to ensure ease of use, even for those new to the technology.

2. Inspired by human adaptability, advanced force control, and precise movement control enable the robot to modify its actions to conform and maintain stable pressure on complex or irregular surfaces.

3. Designed for safe and efficient human-robot interaction, Flexiv's material removal solution can work next to or fully replace manual workstations. With a compact footprint, the debris removal process is streamlined while efficiency and workpiece quality are increased.